Used Progressive Cavity Pump / P-1205

The used progressive cavity pump is already disassembled and can be inspected in our warehouse. Please contact us for an appointment.

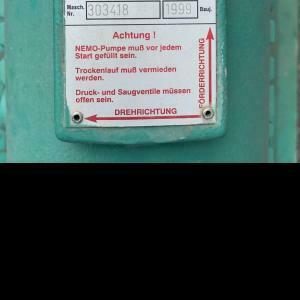

This used progressive cavity pump, or sludge pump is driven by a 5.5 kW motor. The speed is 236 rpm and the discharge pressure is 15 bar. This used progressive cavity pump, type designation NM063SY03S18K, was manufactured by the Germany company Netzsch in 1996 from mild steel.

The dimensions of the used progressive cavity pump are:

L 3200 x W 450 x H 500 mm and it has a weight of approx. 300 kg.

The application of this used sludge pump was the pumping of sewage sludge in a sewage treatment plant.

In our Used Pump Overview you can find more different sized pumps. Should you not find a particular pump, please feel free to contact us, we are happy to assist you.

Technical data of the Used Progressive Cavity Pump

Progressive cavity pump

Progressing cavity pumps are used in all branches of industry for the continuous conveyance of almost all media. In particular, they are used for viscous, highly viscous media such as slurries, slurry, petroleum and greases.

Functional principle of a progressive cavity pump

All progressive cavity pumps belong to the group of rotary positive displacement pumps. The characteristic feature of these pumps is the special design and arrangement of the two conveying elements , the rotor and the stator. The different number of threads of the rotor and stator creates a chamber which opens and closes alternately in an uninterrupted sequence as the rotor rotates, transporting the material continuously from the suction side to the discharge side. Due to the geometric design and the constant contact between the two conveying elements, sealing lines are created which ensure absolute closure between the suction and pressure sides in every position of the eccentric screw, even when the machine is at a standstill.

This seal between the suction and discharge sides gives the pump its high suction capacity. However, it should be noted that wear is very high with abrasive media. This can lead to high operating costs.